Contractor vs Cabinet Saw: Which Table Saw is Right for a Beginner? (2025 Guide)

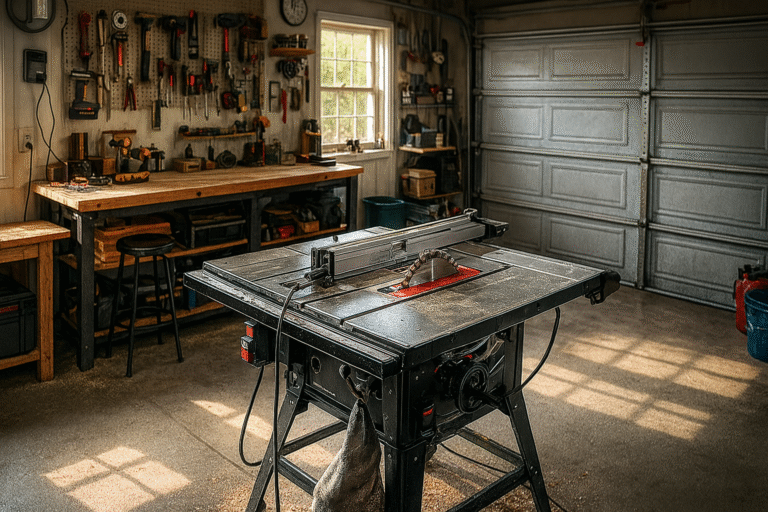

You’re standing in your garage.

You’ve watched the YouTube videos. You’ve read the forums. You’ve stared at the product pages until your eyes blur.

You’re ready to buy your first real table saw — not the wobbly benchtop thing you’ve been wrestling with.

But now you’re stuck.

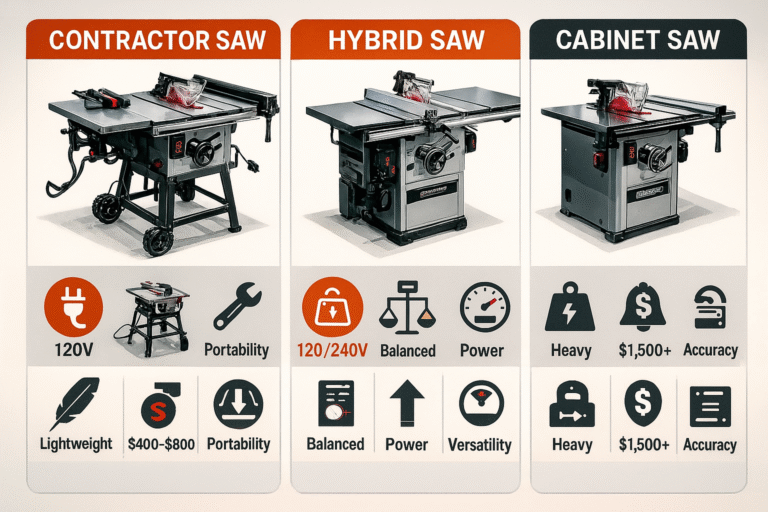

On one side: the contractor saw. Lighter. Cheaper. Fits in your garage. Plugs into your wall.

On the other: the cabinet saw. Heavier. More expensive. Needs its own circuit. Looks like it belongs in a pro shop.

And whispering in your ear: the “hybrid.” “Best of both worlds,” they say.

You don’t just want a saw.

You want the right saw.

The one that won’t gather dust in six months because it’s too frustrating to use.

The one that won’t hold you back when you’re ready to build something beautiful.

The one that won’t make you say, “I wish I’d just spent the extra $200.”

I’ve been there.

And I’m going to walk you through it — step by step, mistake by mistake, dollar by dollar.

No sales pitch. No affiliate-first nonsense.

Just the truth — from someone who bought the wrong saw first… and lived to tell the tale.

My First Saw Story (And Why I’m Writing This)

🧑🔧 Daniel’s Story: I bought a contractor saw in 2015. It was $500 on sale. I thought I was being smart — “I’ll upgrade later.” Big mistake. The fence flexed. The motor bogged down on ¾” oak. Dust flew everywhere. I ruined three projects before I realized: this wasn’t a “starter” tool. It was a frustration machine. I sold it at a loss 18 months later and bought a used hybrid. Best decision I ever made. If I’d known then what I know now… I’d have saved time, money, and a whole lot of swearing.

This guide is what I wish someone had handed me back then.

Let’s break it down — not by specs, but by your life.

The Contractor Saw Explained (The “Start Small” Option)

What it is:

A contractor saw is designed to be portable. It has an open base (no full cabinet), a belt-driven motor hanging off the back, and usually runs on standard 120V household power.

Pros:

✅ Price: Typically $400–$800 new.

✅ Portability: Light enough (70–90 lbs) to move if needed.

✅ Power Source: Plugs into any standard garage outlet.

✅ Space: Smaller footprint. Fits in tight corners.

Cons:

❌ Fence Quality: Often uses a “T-square” fence that flexes or drifts.

❌ Dust Collection: Poor — most sawdust flies out the back.

❌ Power: 1.5–2 HP — struggles with hardwoods or thick stock.

❌ Stability: Lightweight base = more vibration.

Good for: Renters, apartment dwellers, or anyone with a tight budget and limited space. Not ideal if you plan to cut hardwoods regularly or build furniture.

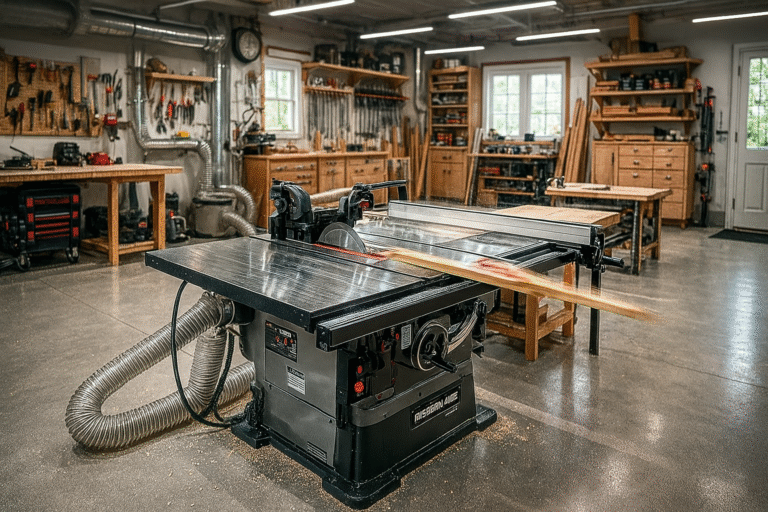

The Cabinet Saw Explained (The “Buy It For Life” Option)

What it is:

A cabinet saw is built like a tank. Full enclosed base, cast-iron top, direct-drive motor inside the cabinet. Usually requires 240V power.

Pros:

✅ Power: 3–5 HP — rips through hardwood like butter.

✅ Accuracy: Industrial-grade fences (like Biesemeyer-style) stay dead-on.

✅ Dust Collection: Sealed cabinet + large port = 80%+ dust capture.

✅ Stability: 400–600 lbs of cast iron = zero vibration.

Cons:

❌ Price: 1,500–$4,000+ new.

❌ **Weight**: Needs a forklift or 4 strong friends to move.

❌ **Power**: Requires a 240V outlet (costs $$ to install if you don’t have one).

❌ Space: Needs a permanent spot — not something you tuck away.

The “Secret” Third Option: Hybrid Saws (The Smart Compromise)

What it is:

A hybrid saw looks like a cabinet saw but weighs less and often runs on 120V. It’s built with some cabinet-saw features (better fence, partial cabinet) but at a contractor-saw price.

Pros:

✅ Price: $800–$1,500 — sweet spot for serious beginners.

✅ Features: Cabinet-style fence, better dust collection, more power (1.75–2.25 HP).

✅ Power: Many run on 120V.

✅ Weight: 250–350 lbs — stable but movable with help.

Cons:

❌ Not a Cabinet Saw: Less power, less mass, less dust control than a true cabinet saw.

❌ Not a Contractor Saw: Heavier and more expensive than entry-level options.

Good for: 90% of beginners. If you’re serious about woodworking but not ready to remodel your garage, this is your sweet spot.

The 5 Key Decision Factors (Answering Your Real Questions)

This is where we cut through the noise.

Forget “HP” and “RPM.” Let’s talk about what actually matters when you’re choosing your first real saw.

Factor 1: Your Budget (New vs. Used)

❓ “How much should a beginner realistically budget for a quality first table saw?”

If you’re buying new:

- $400–$800: Contractor saw (entry-level, limited growth)

- $800–$1,500: Hybrid saw (best value, room to grow)

- $1,500+: Cabinet saw (overkill for most beginners)

If you’re buying used:

You can find incredible deals — a used hybrid or even a cabinet saw for the price of a new contractor saw.

Pro Tip: Check Craigslist, Facebook Marketplace, and local woodworking clubs. Look for saws from retirees — they’re often well-maintained and underpriced.

❓ “What are the pros and cons of buying a used saw vs. a new one?”

Used Pros:

- Save 30–50%

- Often better build quality (older saws were built to last)

- Proven reliability (if maintained)

Used Cons:

- No warranty

- May need tune-up or parts

- Risk of hidden damage

My Advice: If you’re handy and patient, go used. If you want plug-and-play, go new.

Factor 2: Your Workshop (Space & Power)

❓ “What are the real-world space and power requirements for each type of saw in a garage shop?”

Contractor Saw:

- Space: Fits in a corner. Can be moved.

- Power: Standard 120V outlet. No electrician needed.

Hybrid Saw:

- Space: Needs a semi-permanent spot. Not easy to move solo.

- Power: Most run on 120V. Some need 240V — check before buying.

Cabinet Saw:

- Space: Needs a dedicated 6’ x 6’ footprint. Not going anywhere.

- Power: Requires 240V circuit. Installation cost: .

❓ “For a small shop, is a high-end contractor saw a better investment than a budget cabinet saw?”

Short answer: No.

A “high-end” contractor saw still has a flimsy fence and poor dust control. A “budget” cabinet saw doesn’t really exist — they start at $1,500 for a reason.

If you’re in a small shop, a hybrid saw is your best bet. It gives you 80% of the cabinet saw’s performance in 60% of the space.

Factor 3: Your Projects (Performance & Accuracy)

❓ “Beyond the motor, what specific features should a beginner prioritize?”

Your motor matters less than you think.

What matters more:

- Fence Accuracy: If your fence isn’t dead parallel to the blade, nothing else matters.

- Table Flatness: Warped tables = crooked cuts.

- Miter Gauge Slot: Should be clean, tight, and parallel to the blade.

- Trunnion Adjustment: Easy to align? Or a nightmare?

Pro Tip: Before buying, ask: “Can I easily align this saw myself?” If the answer is “You’ll need tools and patience,” keep looking.

Factor 4: The Fence & Miter Gauge (Non-Negotiable Features)

This is where most beginners get burned.

A $2,000 saw with a bad fence is worse than a $600 saw with a great one.

Look for:

- Fence: T-style or Biesemeyer-style. Locks down tight. No flex.

- Miter Gauge: Fits snug in the slot. Has positive stops at common angles (45°, 90°).

- Scale: Easy to read. Not painted on — engraved or laser-cut.

Avoid: “T-square” fences on contractor saws. They drift. They flex. They lie to you.

My Rule: If the fence feels flimsy in the store, it’ll feel worse in your shop.

Factor 5: Safety (Essential Features & Add-ons)

❓ “What essential safety features and accessories are non-negotiable?”

Built-In:

- Blade guard (use it!)

- Riving knife (prevents kickback — DO NOT remove)

- Magnetic switch (turns off if power fails — prevents surprise restarts)

Add-Ons You Need:

- Push sticks (get 3)

- Featherboards (for consistent pressure)

- Micro-adjustable fence (if your saw doesn’t have one)

- Dust collection (your lungs will thank you)

Safety isn’t optional. It’s part of the tool.

Conclusion: My Final Recommendation for Beginners

If you’re just starting out — and you’re serious about building real projects — here’s my advice:

Not because it’s perfect.

But because it’s the smartest compromise.

It’s powerful enough for hardwoods.

Stable enough for precision.

Affordable enough for a beginner.

Compact enough for a garage.

And when you outgrow it? You’ll know exactly what you need next — because you’ll have learned what matters to you.

Don’t buy a contractor saw thinking “I’ll upgrade later.” You’ll just delay your progress.

Don’t buy a cabinet saw thinking “I’ll grow into it.” You’ll drown in complexity and cost.

Buy the hybrid. Learn on it. Build on it. Love it.

Then — when you’re ready — upgrade with confidence.

🛠️ No Matter Which Saw You Choose — Start Here

The single biggest mistake beginners make?

They buy a great saw… then never tune it.

A misaligned blade. A drifting fence. A dull tooth.

That’s how perfect plans turn into ruined projects.

That’s why I created the free “Dead-Square Every Time” Table Saw Tune-Up Checklist.

It’s a simple, 15-minute guide to calibrating your saw for perfect accuracy — whether it’s a $400 contractor or a $2,000 cabinet beast.

t’s not about the saw you buy.

It’s about how you set it up.

Let’s build something great — together.

— Daniel

HMZ Woodz