You know that feeling when you’re standing in front of your table saw, staring at a piece of wood that needs a complex cut, and your heart starts racing? I’ve been there more times than I care to admit. There’s nothing quite like the frustration of knowing exactly what you want to achieve but feeling like your saw just isn’t capable of getting you there safely and accurately.

I remember early in my woodworking journey, I was trying to cut tapers for a coffee table project. After three ruined boards and nearly losing a finger (please don’t ask), I realized something crucial: the table saw isn’t just about the blade – it’s about the jigs and accessories that help you harness its full potential. That’s when I discovered the game-changing world of DIY table saw jigs for precise cuts.

Why These Jigs Will Transform Your Woodworking

Here’s the truth I wish someone had told me years ago: your table saw is only as good as the jigs you use with it. A basic table saw with well-made jigs will outperform an expensive cabinet saw with poor setups every single day. These five jigs I’m about to share with you aren’t just nice-to-have accessories – they’re the difference between struggling through every complex cut and confidently tackling projects that once seemed impossible.

What you’re about to learn will help you:

- Make repeatable, precise cuts that fit perfectly every time

- Work safely with small pieces and odd angles

- Create professional-looking joints without expensive specialty tools

- Build your confidence and expand what’s possible in your shop

The Foundation: What Makes a Great Table Saw Jig

Before we dive into building these jigs, let me share what I’ve learned makes the difference between a jig that sits on your shelf collecting dust and one you’ll reach for every single project.

First, accuracy is everything. A jig that’s off by even a hair will compound that error across every cut. Second, safety should never be compromised – these jigs should keep your hands far from the blade while giving you complete control. Finally, they need to be simple enough that you’ll actually use them, not so complex that setting them up takes longer than making the cut.

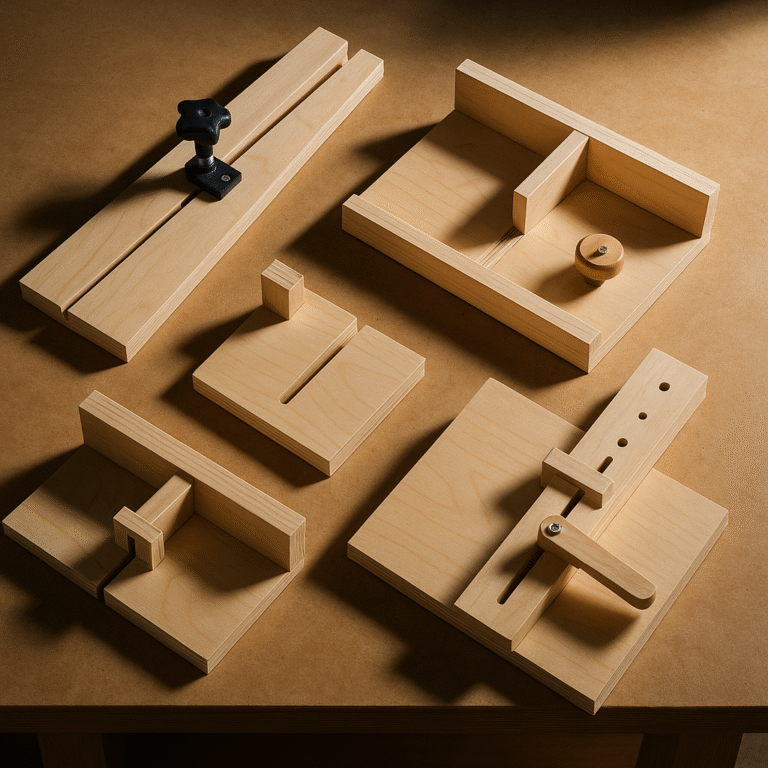

Jig #1: The Tapering Jig – Your Gateway to Perfect Angles

Why You Need This Jig

The tapering jig was my first real “aha!” moment with table saw sled ideas. Whether you’re making table legs, creating wedges, or cutting any angled piece, this jig eliminates the guesswork and keeps your hands safe.

What You’ll Need

- 3/4″ plywood base (12″ x 24″)

- 1″ x 2″ hardwood strip

- Toggle clamps

- Adjustable hinge or simple pivot mechanism

- Wood screws and glue

Building Your Tapering Jig

Step 1: Create the Base Start with your plywood base. I like to use Baltic birch because it stays flat, but any good-quality 3/4″ plywood will work. Sand it smooth – you’ll be sliding wood across this surface, so any roughness will show up in your cuts.

Step 2: Install the Fixed Fence Attach your 1″ x 2″ strip along one long edge of the base. This becomes your fixed fence that rides against the table saw’s fence. Make sure it’s perfectly straight and square to the base – use your best square here, and double-check it.

Step 3: Create the Adjustable Fence The magic happens with the adjustable fence. I’ve seen complex mechanisms, but honestly, a simple hinge at one end with measurement marks works beautifully. Position the hinge about 4″ from the end of your base, and create degree markings for common angles.

Step 4: Add Workpiece Support This is where many DIY jigs fall short. Add a cleat or toggle clamp system to securely hold your workpiece. Trust me, a piece that shifts mid-cut ruins your day fast.

Using Your Tapering Jig

Set your desired angle, clamp your workpiece firmly, and run the jig along your table saw fence. The key is consistent, steady pressure – don’t rush the cut. I’ve found that a slightly slower feed rate gives cleaner results with less tear-out.

Jig #2: Small Parts Sled – Tackle Tiny Pieces Safely

The Problem This Solves

Here’s a scenario every woodworker faces: you need to cut small pieces, but they’re too tiny to safely guide past the blade. Your push stick feels awkward, your fingers are getting dangerously close to the action, and the pieces keep shifting. Sound familiar?

Building Your Small Parts Sled

Materials Needed:

- 1/2″ plywood base (8″ x 12″)

- 3/4″ x 1-1/2″ hardwood runners

- Small toggle clamp

- Sandpaper strip for grip

Construction Steps:

Step 1: Prepare the Base Cut your plywood base perfectly square. I can’t stress this enough – if your base isn’t square, nothing you cut with it will be either. Use your miter gauge as a reference to ensure the leading edge is perfectly perpendicular to the blade path.

Step 2: Install Runners Create runners that fit snugly in your miter slots. They should slide smoothly but without any play. I use hardwood for runners because it wears better than plywood and can be fine-tuned with sandpaper.

Step 3: Add Hold-Down System Install a small toggle clamp positioned so it can secure pieces while keeping your hands well clear of the blade. I also add a strip of fine sandpaper to the base where the workpiece sits – this prevents shifting during the cut.

Step 4: Create Reference Lines Mark clear reference lines on your sled for common cuts. I have lines for 90 degrees, 45 degrees, and 22.5 degrees. These visual guides speed up setup and reduce errors.

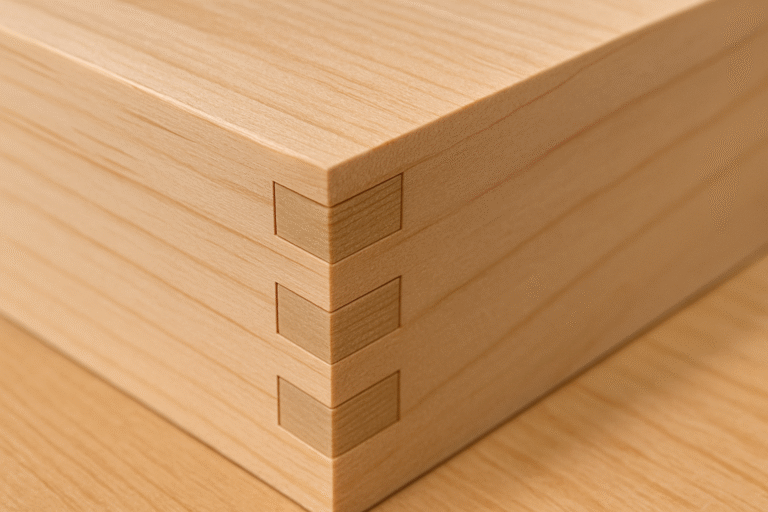

Jig #3: Box Joint Jig – Perfect Fingers Every Time

Why This Jig Changes Everything

Box joints look incredibly complex, but with the right jig, they’re actually quite straightforward. I remember spending hours trying to cut them by hand, getting frustrated with gaps and misaligned fingers. This jig solved all those problems in one afternoon of building.

Construction Details

Materials:

- 3/4″ plywood base (10″ x 16″)

- Hardwood runners for miter slots

- Adjustable fence system

- Indexing pin (hardwood dowel)

Step 1: Build the Base Platform Create a solid base that tracks smoothly in your miter slots. The fence needs to be adjustable both for different box joint sizes and to fine-tune the fit.

Step 2: Create the Indexing System Here’s where the magic happens: the indexing pin. This pin, cut from the same setup that cuts your box joints, ensures each finger is perfectly spaced. When you cut your first slot, the pin fits into it. For the next cut, you shift the workpiece so the previous cut slides onto the pin.

Step 3: Test and Adjust Cut test joints in scrap wood first. The fit should be snug but not require hammering together. If joints are too tight, shift the fence slightly away from the blade. Too loose? Move it toward the blade by tiny increments.

Jig #4: Spline Jig – Strengthen Your Miters

Understanding Splines

Splined miters are one of those techniques that separate amateur work from professional-looking projects. A spline is essentially a thin strip of wood that fits into matching grooves cut across a miter joint, dramatically increasing the glue surface and mechanical strength.

Building the Spline Jig

What You’ll Need:

- 3/4″ plywood base (8″ x 10″)

- 45-degree support block

- Miter slot runners

- Safety barrier

Step 1: Create the 45-Degree Support Cut a 45-degree support block that holds your mitered assembly at the correct angle to the blade. This block needs to be rock-solid – any movement here ruins the joint.

Step 2: Add Safety Features Install a clear barrier or guard that keeps your hands away from the blade while allowing you to see the cut. I use a piece of clear polycarbonate attached to the jig.

Step 3: Test Your Setup Always test with scrap pieces cut from the same stock as your project. The spline groove should be centered on the miter and deep enough for good strength without weakening the joint.

Jig #5: Tenoning Jig – Rock-Solid Mortise and Tenon Joints

Why Vertical Cutting Matters

The tenoning jig holds your workpiece vertically, allowing you to cut tenon cheeks with the grain rather than across it. This creates cleaner cuts and stronger joints than trying to wrestle wide boards flat on the saw table.

Construction Approach

Materials Required:

- 3/4″ plywood back (12″ x 16″)

- 2″ x 4″ base for stability

- Adjustable clamp system

- Safety handle positioned well away from blade

Building Steps:

Step 1: Create a Stable Base The base needs enough weight and width to prevent tipping. I use a 2″ x 4″ base with the jig back attached at exactly 90 degrees. Check this with your most trusted square.

Step 2: Install Clamping System Position clamps so they can secure various workpiece sizes while keeping the pressure even. Uneven clamping leads to workpieces shifting mid-cut – never a good thing.

Step 3: Add Fine Adjustment Include a micro-adjustment system for fine-tuning tenon thickness. This might be as simple as shims or as sophisticated as an adjustable fence with measurement marks.

Essential Safety Tips for All Jigs

Let me be crystal clear about something: these jigs are only helpful if you use them safely. Here are the non-negotiable safety rules I follow:

- Always use a blade guard when possible

- Keep push sticks and push blocks handy

- Never reach over or around the blade

- Secure all clamps before starting the saw

- Test every setup with scrap wood first

- Keep your workspace clean and well-lit

Common Mistakes to Avoid

Mistake #1: Rushing the Build Process

I’ve seen too many woodworkers throw together a quick jig for one project, only to have it fail when they need it most. Take time to build these jigs right the first time. Use good materials, check your measurements twice, and test thoroughly.

Mistake #2: Ignoring Seasonal Movement

Wood moves with humidity changes, and your jigs are made of wood. I learned this the hard way when my “perfect” box joint jig started producing sloppy joints after a humid summer. Account for this by using stable materials like Baltic birch plywood and checking your jigs periodically.

Mistake #3: Over-Complicating the Design

Some of the best homemade table saw accessories are surprisingly simple. Don’t add complexity for its own sake. If a simple toggle clamp does the job, there’s no need for an elaborate cam system.

Mistake #4: Poor Dust Management

Sawdust buildup affects accuracy. Design your jigs with dust collection in mind, or at least easy cleanup. A small shop vacuum attachment point can make a huge difference in how well your jigs perform over time.

Fine-Tuning Your Jigs for Maximum Accuracy

Building the jig is only half the battle – getting it perfectly dialed in is where the magic happens. Here’s my process for achieving the precision that makes these jigs worthwhile:

The Test Cut Protocol

For every jig, I have a specific test sequence:

- Set up the jig with scrap wood identical to my project material

- Make test cuts and measure the results

- Adjust and test again until the results are perfect

- Only then make cuts on project wood

Micro-Adjustments Matter

The difference between a good cut and a perfect cut often comes down to adjustments measured in thousands of an inch. Don’t be afraid to make tiny tweaks. Shims made from masking tape, business cards, or thin wood can dial in that perfect fit.

Maintaining Your Jigs for Long-Term Success

These aren’t build-once-and-forget tools. Like any precision instrument, they need maintenance to stay accurate:

Regular Inspections

Check runners for wear, ensure fences stay square, and verify that clamps still hold firmly. I do a quick inspection every few months or whenever something doesn’t feel right.

Seasonal Adjustments

As humidity changes throughout the year, you might need to adjust fence positions or runner fits. Keep notes about seasonal adjustments so you know what to expect.

Storage Solutions

Protect your investment by storing jigs properly. I hang mine on the wall where they’re visible and accessible but protected from damage. A dedicated jig cabinet is even better if you have the space.

Expanding Your Jig Collection

These five jigs cover a lot of ground, but they’re just the beginning. As your skills grow, you’ll identify other cutting challenges that could benefit from specialized jigs. The principles you learn building these will apply to any future jig projects.

Some table saw sled ideas for your next builds might include:

- Crosscut sleds for different material sizes

- Picture frame jigs for perfect miters

- Cove cutting jigs for decorative profiles

- Dado jigs for shelf and cabinet work

Troubleshooting Common Issues

Jig Doesn’t Track Straight

This usually means your runners don’t fit the miter slots properly. They should slide smoothly but without side-to-side play. Adjust with sandpaper or thin shims.

Inconsistent Cut Quality

Check that your workpiece is flat against the jig and securely clamped. Any movement during cutting shows up in the finished product. Also verify your blade is sharp and appropriate for the material.

Measurements Don’t Match Setup

Double-check that your measuring system accounts for blade kerf width. Many beginners forget that the blade removes material equal to its thickness.

The Confidence Factor

Here’s something I want you to understand: these jigs aren’t just about making better cuts – they’re about building your confidence as a woodworker. When you know you can tackle complex cuts safely and accurately, it opens up a whole world of project possibilities.

I’ve watched woodworkers transform from tentative beginners to confident craftspeople simply by mastering a few key jigs. The difference isn’t just in their technical skills – it’s in their willingness to attempt more challenging projects because they know their tools will support their ambitions.

Taking Your Skills to the Next Level

Now that you understand these five essential DIY table saw jigs for precise cuts, you’re equipped to tackle projects that might have seemed impossible before. But remember, the best jig is worthless if your table saw isn’t properly set up and maintained.

That’s where many woodworkers fall short. They build beautiful jigs and then wonder why their cuts still aren’t perfect. The answer often lies in basic saw maintenance and calibration that gets overlooked in the excitement of new projects.

Your table saw needs to be properly aligned, with the blade parallel to the miter slots and fence. The fence needs to be square to the table and lock down solidly. The blade should be sharp and appropriate for your material. These fundamentals make the difference between good results and great ones.

Your Next Steps

These jigs represent hours of refined design and testing. They’ll serve you well for years if built properly and maintained regularly. Start with the tapering jig if you’re new to jig building – it’s forgiving and immediately useful. Once you’ve mastered that, move on to the others based on your project needs.

Remember, every expert woodworker was once a beginner who felt overwhelmed by complex cuts. The difference is they learned to build and use jigs that made those cuts routine. You’re now equipped with the knowledge to do the same.

Don’t be afraid to modify these designs for your specific needs. The dimensions I’ve given work well for most situations, but your shop, your saw, and your projects might benefit from adjustments. That’s not just okay – it’s encouraged. The best jigs are often the ones customized for specific needs.

Conclusion

Building these five essential jigs – the tapering jig, small parts sled, box joint jig, spline jig, and tenoning jig – will fundamentally change how you approach woodworking. They’ll expand what’s possible in your shop while making complex cuts safer and more accurate than you ever thought possible.

These aren’t just tools; they’re confidence builders. Each successful cut reinforces your skills and encourages you to tackle more challenging projects. That’s the real value here – not just better cuts, but the satisfaction that comes from mastering your craft one jig at a time.

The journey from struggling with basic cuts to confidently tackling complex joinery doesn’t happen overnight, but these jigs will accelerate your progress dramatically. Take the time to build them right, learn to use them properly, and maintain them well. Your future projects will thank you for the investment.

Ready to Ensure Your Table Saw Is Perfectly Dialed In?

These jigs are only as good as the table saw they’re used with. Before you start building, make sure your saw is properly calibrated and maintained. Download our free “Table Saw Tune-Up Checklist” to ensure your workshop’s core tool is perfectly aligned and ready to deliver the precision these jigs demand. This comprehensive checklist walks you through every adjustment and maintenance task needed to get professional results from any table saw.

Don’t let a poorly calibrated saw sabotage your beautiful jigs and careful work. Get your checklist now and start every project with confidence!