Is your table saw not cutting square? Ugh, nothing’s more frustrating than measuring twice and cutting… crooked. You know the drill – you’ve triple-checked everything, lined it up like you’re launching a rocket to Mars, and somehow your cut is still wonkier than a three-legged chair.

Trust me, I’ve been there more times than I’d like to admit. Twenty years of woodworking, and I still remember the early days when my table saw not cutting square made every project a nightmare. The good news? Most table saw troubleshooting comes down to seven sneaky little problems that love to mess with your head.

Why Your Table Saw Not Cutting Square: The 7 Sneaky Culprits Behind Your Crooked Cuts

1. Your Fence is Playing Games With You

Okay, this one’s the troublemaker about 60% of the time. Your fence looks parallel to the blade, but it’s actually off by just a hair – and that hair might as well be a mile when you’re trying to get perfect cuts.

The Fix: Grab a straight edge (I use my trusty 4-foot ruler) and measure from the fence to the blade at the front, then at the back. They better match, or you’ve found your problem! Most fences have adjustment bolts that’ll let you dial it in. Don’t rush this part – it’s like tuning a guitar, you gotta get it just right.

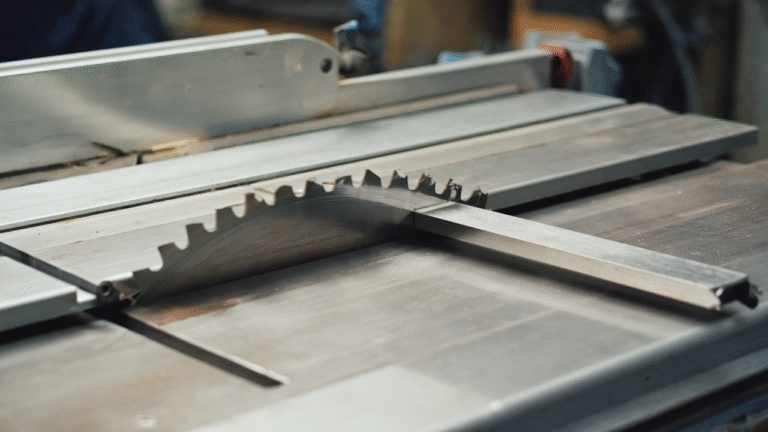

2. Your Blade’s Doing the Wobble

Here’s a sneaky one that’ll drive you nuts: blade deflection. Your blade’s actually bending while it cuts, especially those thin-kerf blades when you’re pushing through thick hardwood. It’s like trying to cut with a wet noodle.

The Fix: First off, match your blade to your wood. Thick oak? Use a full-kerf blade, not that flimsy thin one. Second, slow down, cowboy! If you’re sweating while feeding the wood, you’re pushing way too hard. Let the blade do its thing.

3. Your Table’s Having an Identity Crisis

Your saw’s table should be flatter than a pancake. Even a tiny warp will rock your workpiece around like a boat in choppy water, making square cuts basically impossible.

The Fix: Get a precision straight edge and check your table surface. Any gaps bigger than a few thou means trouble and explains why your table saw not cutting square. Small warps? You might get away with some strategic shimming. Big warps? Time to call in the pros or start shopping for a new saw.

4. Your Blade’s Seen Better Days

A dull blade doesn’t just cut slow – it wanders around like it’s had too much coffee. Pitch buildup or chipped teeth will pull that blade off course faster than you can say “table saw not cutting square.”

The Fix: Take a close look at those teeth. If they’re rounded instead of sharp, or covered in gunk, it’s time for some TLC. A sharp blade should slice through your test piece like butter. When in doubt, throw in a fresh blade – you’ll be shocked at the difference.

5. You’re Playing Goldilocks With Blade Height

Too high, too low, but never just right! I see this mistake all the time. People either crank it way up “for safety” or barely peek it above the wood “to be careful.” Both ways mess up your cuts.

The Fix: Set your blade about 1/4 inch above your workpiece. Too high and you get nasty tear-out (and potential kickback). Too low and the blade deflects more, plus you’re cutting with the sides of the teeth instead of the sharp tips.

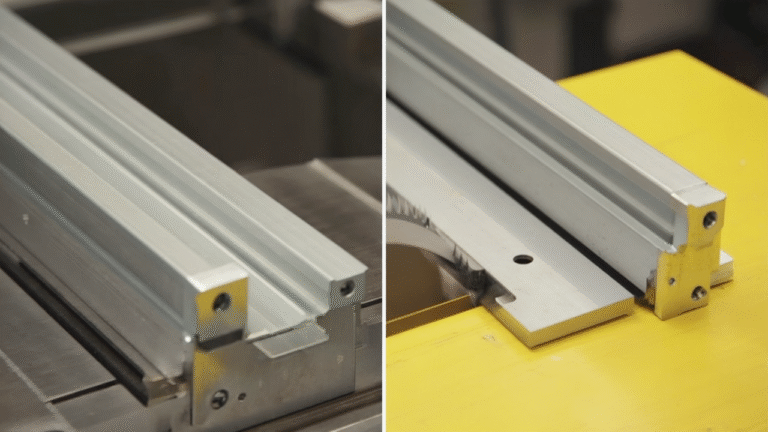

6. Your Miter Gauge is Looser Than a Screen Door

If your miter gauge wiggles around in its slot like a hot dog in a hallway, you’re never gonna get consistent cuts. It needs to slide smooth but stay put side-to-side.

The Fix: Give that miter gauge a wiggle test. If there’s play, most have little adjustment screws you can tighten. If your slots are really worn out, consider upgrading to an aftermarket miter gauge – your future self will thank you.

7. Your Wood’s Not Getting the Support it Needs

This one’s subtle but super important. If your workpiece isn’t supported properly through the whole cut, it’ll shift or bind and throw everything off.

The Fix: Get yourself some outfeed support and side supports for bigger pieces. Even a cheap roller stand makes a world of difference. For long boards, grab a buddy to help – it’s not just safer, it’s way more accurate too.

Table Saw Not Cutting Square? Playing Detective to Find Your Problem

Don’t just start adjusting stuff willy-nilly – that’s a recipe for making things worse. Here’s my game plan:

- Make a test cut on some scrap that’s at least 12 inches wide

- Check it with a good square (get a real machinist’s square, not one of those speed squares)

- Figure out where the problem happens – start of the cut? End? The whole dang thing?

- Work through the list starting with fence alignment (it’s usually the fence!)

Work through each thing methodically. Sometimes it’s not just one problem – a bunch of little issues can gang up on you and create one big headache.

Staying Ahead of the Game

The best fix? Don’t let problems happen in the first place:

- Weekly check: Fence alignment and blade sharpness

- Monthly deep dive: Table flatness, miter gauge fit, general cleanliness

- Seasonal tune-up: Complete recalibration of everything

- Keep notes: Write down what you adjust and why

I’ve got a simple checklist taped inside my saw cabinet. Takes five minutes but saves me hours of frustration later. Smart, right?

When to Wave the White Flag

Look, some problems are above our pay grade. If your table’s seriously warped, your arbor’s bent, or you’re just not comfortable making adjustments, find a good repair shop. It’s cheaper than buying a new saw or dealing with something dangerous.

Also, if you’ve tried all seven fixes and your saw’s still giving you crooked cuts, there might be something fundamentally wrong that needs professional eyes.

You’re Gonna Nail This

Here’s what I want you to remember: every single woodworker has fought this battle. The difference between tearing your hair out and actually enjoying your hobby isn’t some magical talent – it’s just understanding your tools and taking the time to set them up right.

Start with that fence alignment tomorrow morning. It’s the most common problem and the easiest fix. Once you see how much difference proper setup makes, you’ll wonder why you put up with wonky cuts for so long.

Your projects deserve to fit together perfectly, and you deserve the satisfaction of cuts that actually work. Take control of your table saw troubleshooting, and it’ll reward you with years of spot-on service.

Ready to kiss crooked cuts goodbye forever? Grab our complete table saw tune-up checklist – it walks you through every single adjustment with photos and troubleshooting tips that’ll make you look like a pro.