I’ve seen too many fingers shorter than they should be…

Table saw safety tips aren’t just suggestions – they’re the difference between a successful woodworking career and a trip to the emergency room. Let me paint you a picture that’ll make your stomach turn – and hopefully save your digits. Last spring, I was teaching a weekend workshop when a student, let’s call him Mike, got a little too comfortable with his new table saw. One moment of inattention, one casual reach across the blade, and suddenly we were rushing to the emergency room with Mike’s fingertip wrapped in shop towels.

That day changed everything for me as an instructor. Mike’s injury wasn’t from some freak accident or equipment failure – it was completely preventable with proper table saw safety tips. And that’s what haunts me about most woodworking safety incidents.

Table Saw Accidents Prevention: The Reality Check

Here’s the truth about woodworking safety that’ll make you reconsider that “just this once” attitude: According to the Consumer Product Safety Commission, table saws cause over 30,000 injuries annually in the United States alone. That’s roughly 82 people every single day walking into emergency rooms with table saw injuries.

But here’s the kicker for table saw accidents prevention – nearly 90% of these accidents could have been prevented with proper safety practices. I’m not talking about elaborate safety systems or expensive equipment (though those help). I’m talking about basic techniques that take zero extra time once you build the habit.

As someone who’s been working with wood for over 15 years and has taught hundreds of beginners, I can tell you that the difference between a safe woodworker and an injured one usually comes down to five non-negotiable table saw safety tips. These woodworking safety rules are what separate the pros from the accident statistics.

Table Saw Safety Tips Rule #1: Never Remove Your Blade Guard Unless Absolutely Necessary

I get it – blade guards can feel clunky and seem to get in the way. I’ve heard every excuse in the book: “I can’t see the cut line,” “It’s just a quick crosscut,” or my personal favorite, “I’m experienced enough.”

Here’s my response: The blade guard is there for the moments when you’re NOT thinking clearly. Fatigue, distraction, or simple overconfidence – these are when accidents happen.

What to do instead:

- Adjust your lighting so you can see through or around the guard

- Use auxiliary fences and jigs that work with your guard in place

- If you absolutely must remove it for specialized cuts, replace it immediately afterward

I learned this lesson the hard way early in my career. I was making dado cuts (which require guard removal) and got distracted by a phone call. Three cuts later, I realized I’d been working without the guard for an hour. Nothing happened that day, but it was a wake-up call about how easy it is to forget.

Woodworking Safety Rule #2: Master Proper Push Stick Technique

This is where I see beginners make their biggest woodworking safety mistakes. They either don’t use push sticks at all, or they use them incorrectly, which can actually be more dangerous than not using them. These table saw safety tips for push sticks are crucial:

The right technique:

- Keep push sticks within arm’s reach at all times

- Use two hands when possible – one to guide, one to push

- Never push directly behind the blade; offset your pressure

- The push stick should be long enough to keep your hand at least 6 inches from the blade

Common mistakes I see:

- Using push sticks that are too short

- Pushing straight down instead of forward and down

- Trying to retrieve cut-offs while the blade is still spinning

I always tell my students: “Your push stick is cheaper than your finger, and it grows back faster too.” Make several – I keep at least three different sizes in my shop.

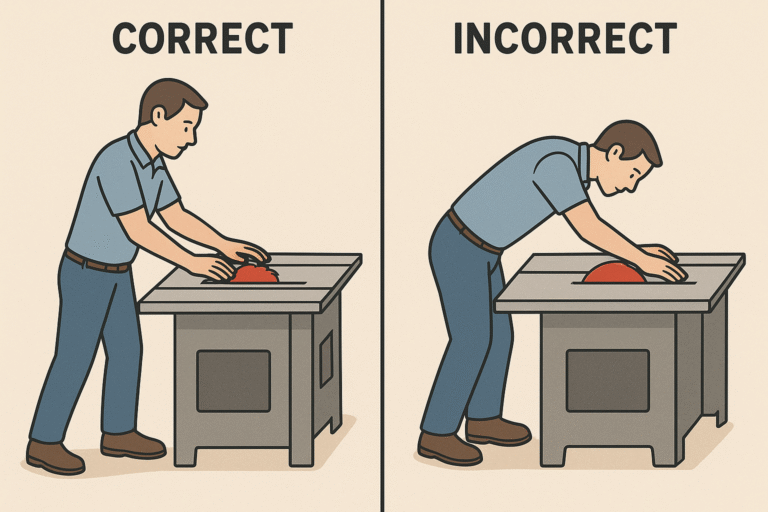

Table Saw Safety Tips Rule #3: Get Your Body Positioning Right

This might be the most overlooked aspect of table saw accidents prevention, but it’s absolutely critical. Poor body positioning doesn’t just increase injury risk – it also leads to poor cuts and dangerous kickback situations.

The safe stance:

- Stand slightly to the left of the blade, never directly behind it

- Keep your feet planted and balanced

- Lean slightly forward, but never let your body cross the blade line

- Keep your face and chest away from the direct line of potential kickback

I remember working with a student who kept leaning over the saw to watch the cut. I must have corrected him five times before he said, “But I can’t see what I’m doing!” That’s when I realized he needed better lighting and a different approach to marking his cuts. Fix the setup, not your safety habits.

Essential Table Saw Safety Tips Rule #4: Understand and Prevent Kickback

Kickback is probably the most dangerous thing that can happen with a table saw, and it’s often misunderstood by beginners. When it comes to table saw accidents prevention, understanding kickback is crucial. When a piece of wood gets grabbed by the blade and thrown back at you at 100+ mph, you don’t want to be in its path.

Kickback happens when:

- The wood pinches the blade (usually from poor fence setup)

- You’re cutting without proper support

- The wood lifts off the table during the cut

- You’re trying to cut warped or twisted lumber

Prevention strategies:

- Always use a riving knife (that thin metal piece behind the blade)

- Keep your fence parallel to the blade

- Never cut freehand – always use the fence or miter gauge

- Support long pieces with outfeed tables or stands

- Never try to back out of a cut while the blade is running

Three years ago, I was helping a friend cut some reclaimed lumber that had a slight bow to it. We didn’t take time to flatten it first, and when that board grabbed the blade, it launched across the shop like a missile. Thankfully, neither of us was in its path, but it put a dent in my shop wall that I keep as a reminder.

Woodworking Safety Rule #5: Know Where Your Emergency Shut-Off Is

In an emergency, every second counts when it comes to table saw accidents prevention. You need to be able to shut off your saw without thinking about it, even if you’re injured or panicked.

Emergency preparedness:

- Know exactly where your switch is and practice hitting it blindfolded

- Consider adding a large paddle switch or emergency stop button

- Keep the area around the switch clear

- Have a first aid kit readily available

- Know the fastest route to your phone

I installed a knee-activated emergency switch after Mike’s accident. It cost me $40 and 30 minutes to install, and it gives me incredible peace of mind.

Essential Woodworking Safety Gear That Actually Works

These table saw safety tips for equipment selection can make the difference between a close call and a serious injury. Let’s talk about gear that actually makes a difference in woodworking safety:

Must-haves:

- Safety glasses (not safety squints)

- Hearing protection – table saws are LOUD

- Push sticks (plural – have backups)

- Featherboards for consistent pressure

- A good dust mask

Nice-to-haves that become must-haves:

- SawStop or similar flesh-detecting technology

- Outfeed table for long pieces

- Mobile base for better positioning

Don’t cheap out on safety glasses. I’ve seen too many people wearing glasses from the hardware store bargain bin that fog up or slip during use. Get properly fitted safety glasses that you’ll actually want to wear.

When NOT to Use Your Table Saw

Sometimes the smartest safety decision is knowing when to walk away. Don’t use your table saw when you’re:

- Tired or distracted

- Rushing to meet a deadline

- Under the influence of anything (including some medications)

- Working alone on large or dangerous cuts

- Fighting with warped, twisted, or damaged lumber

I have a personal rule: If I find myself thinking “this doesn’t feel right,” I stop. Every time. That gut feeling has saved me more than once.

Emergency Response Plan

Hope for the best, prepare for the worst. Here’s what every workshop needs:

Before an accident:

- Keep a well-stocked first aid kit near your saw

- Have emergency numbers posted visibly

- Know your blood type and any medical conditions

- Tell someone when you’re working alone

During an emergency:

- Turn off the saw immediately

- Don’t move an injured person unless they’re in immediate danger

- Apply direct pressure to bleeding wounds

- Call 911 – don’t try to drive yourself with a serious injury

After an accident:

- Learn from what happened

- Review and update your safety practices

- Don’t let fear keep you from woodworking, but do let wisdom guide you

The Bottom Line: Your Fingers Are Worth More Than Time Saved

Look, I know safety talk can feel like nagging. I know you want to get to the fun part of building something beautiful. But here’s what I’ve learned after years in the shop and teaching others:

The most successful woodworkers aren’t the ones who take the most risks – they’re the ones who develop safe habits and follow essential table saw safety tips so ingrained that they happen automatically. They’re the ones still making sawdust with all ten fingers decades into their craft.

Every shortcut you don’t take, every woodworking safety step you don’t skip, every moment you pause to think “is this safe?” – that’s not wasted time. That’s an investment in table saw accidents prevention and all the future projects you’ll be able to complete with steady hands and clear confidence.

Mike, the student I mentioned earlier, is back in the shop now. His fingertip eventually healed (mostly), but more importantly, he’s become one of the safest woodworkers I know. He tells me that losing part of his finger was the most expensive lesson he ever learned – but also the most valuable.

Don’t let it take an injury to make you take these table saw safety tips seriously. Your future self, your family, and your woodworking dreams will thank you for developing good woodworking safety habits now.

Ready to Master Table Saw Safety Tips?

Woodworking safety isn’t a destination – it’s a journey of continuous learning and improvement. If you found these table saw safety tips helpful and want to dive deeper into table saw accidents prevention, I’ve put together a comprehensive safety checklist that covers not just table saw safety tips, but complete workshop safety protocols.

– it includes setup tips that’ll make your cuts safer AND more accurate. Because the best safety feature on any tool is a knowledgeable operator who takes the time to do things right.

Remember: In woodworking, as in life, it’s better to be safe than sorry. And it’s definitely better to be safe than fingerless.

Stay safe out there, and keep making sawdust the smart way.