Workshop Efficiency Tips: 12 Pro Strategies That Double Your Productivity

I’ll never forget the weekend I “lost.”

I’d planned to build a simple coffee table.

Saturday morning: fired up the saw, cut the legs.

By Sunday night?

I was still looking for my marking gauge.

My clamps were buried under offcuts.

My router bit was dull, but I couldn’t find my sharpening kit.

And my coffee table?

Half-assembled. Frustrated. Abandoned.

That’s when I realized:

My problem wasn’t skill. It was workflow.

Most woodworkers think productivity is about working faster.

But the real pros know:

Efficiency is about working smarter.

After 15 years of teaching — and wasting my own weekends — I’ve cracked the code.

And today, I’m giving you the exact 12 workshop efficiency tips that let me finish projects in half the time — without rushing, without stress, and without losing a single tool.

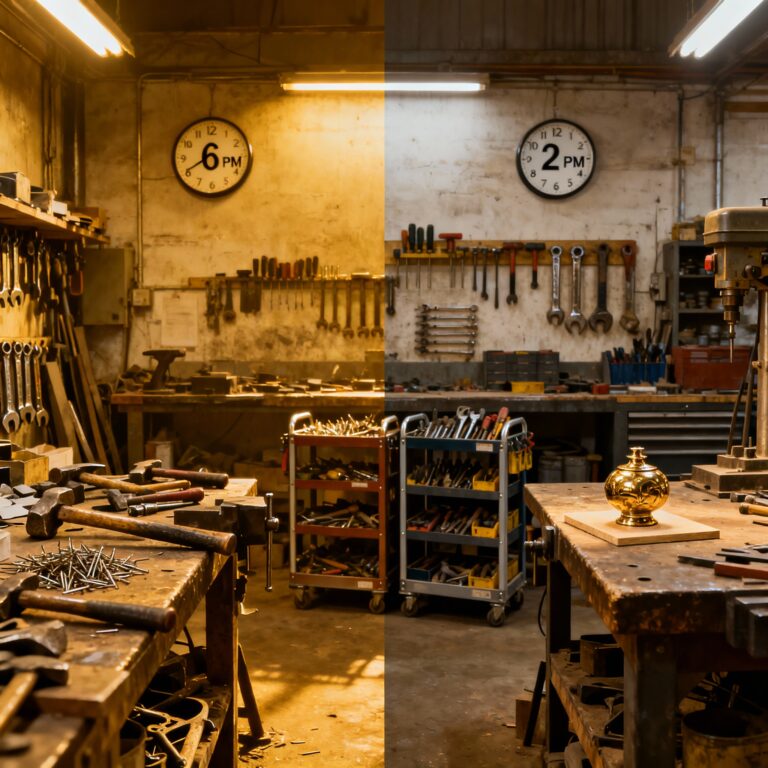

Why Most Woodworkers Waste Hours (Without Realizing It)

Most beginners make one of three mistakes:

- They work in “hero mode” → One cut at a time, one tool at a time.

- They ignore setup time → 80% of the job is prep — not cutting.

- They don’t batch tasks → Constantly switching between measuring, cutting, sanding.

But the real secret?

Productivity isn’t about speed. It’s about flow.

Build a system, and your shop becomes a machine.

The 12 Workshop Efficiency Tips That Actually Work

These aren’t theoretical. They’re the exact habits I use — and teach — to finish projects faster.

🧠 Planning Phase (Save 2 Hours Before You Cut)

Tip 1: The 10-Minute Project Map

Before you touch wood, sketch your entire build with cut list, tool list, and sequence.

🧑🔧 Daniel’s Story: I used to “wing it.” Now, I map every project. Saved me 3 hours on my last bookshelf.

Tip 2: Gather All Tools First

Pull every tool you’ll need and lay it out. No mid-project hunting.

Pro Tip: Use a rolling cart as your “project station.”

Tip 3: Pre-Cut All Material at Once

Mill all your wood in one session — don’t cut one piece, then sand, then cut another.

🔪 Cutting Phase (Cut Smarter, Not Harder)

Tip 4: Batch Identical Cuts

Clamp 4 boards together and rip them in one pass.

Tip 5: Use Stop Blocks for Repetition

Set a block on your fence or miter gauge. Every cut is identical — no measuring.

Tip 6: Tune Your Saw Once, Cut Perfectly Forever

A misaligned saw = wasted time fixing bad cuts.

📌 Start with our Table Saw Blade Alignment Guide .

🛠️ Assembly Phase (Glue-Up Without Panic)

Tip 7: Dry-Fit the Night Before

Assemble dry the night before glue-up. Rehearse clamping. Sleep easy.

Tip 8: Pre-Load Clamps

Set all clamps in position before applying glue. No fumbling with wet joints.

Tip 9: Use Assembly Jigs

Build a simple jig for box assembly. Parts stay aligned. Clamping is faster.

🧹 Cleanup & Flow (The Hidden Time-Savers)

Tip 10: The 5-Minute Reset

After every major step, reset your space: sweep, return tools, clear the floor.

Tip 11: Label Everything

Use a Sharpie: “Project Clamps,” “Table Saw Jigs,” “Router Bits.” No more guessing.

Tip 12: Track Your Time (Just for One Week)

Use your phone timer. You’ll be shocked where your hours go.

📌 For a full system, see our Small Workshop Organization Guide .

Real Results: Maria’s Productivity Leap

Maria, a student of mine, used to spend 20 hours on a simple shelf.

After implementing these tips:

- Batch cutting → 4 identical shelves in the time of 1

- Project cart → Zero tool hunting

- Dry-fit night before → Glue-up in 15 minutes

Result:

- 10-hour projects → 5 hours

- Zero abandoned builds

- Actually enjoys weekends again

“It’s not working harder. It’s working with a plan.”

Common Mistakes to Avoid

❌ Skipping the plan → Leads to mid-project chaos

❌ Ignoring dust → Cleaning takes longer than preventing

❌ Using dull tools → Slows you down and ruins cuts

❌ Not batching → Constant setup = wasted time

❌ Working tired → Mistakes double your time

Before You Start Your Next Project — Tune Your Saw

Here’s the truth no one tells you:

Your workshop efficiency starts with your table saw.

If your saw isn’t tuned, you’ll waste hours fixing crooked cuts, binding joints, and kickback scares.

I used to blame my schedule. My wood. My clamps.

Then I realized: my saw was off by 1/32”. That’s all it took to ruin the flow.

That’s why I created the FREE “Dead-Square Every Time” Table Saw Tune-Up Checklist.

It’s a 15-minute guide to calibrating your saw for perfect 90° cuts — no dial indicator needed.

It’s the first step to a faster shop — and more finished projects.

You’ve Got This

Efficiency isn’t about being perfect.

It’s about building systems that work for you.

Pick 3 tips from this list.

Try them on your next project.

Watch your time shrink — and your confidence grow.

Because the best woodworkers aren’t the fastest.

They’re the most intentional.

Go build something great — and finish it before dinner.

— Daniel

HMZ Woodz