5 Essential Table Saw Jigs Every Beginner Should Build First (Under $20 Each)

You know that feeling?

You’ve got a project in mind. You’ve cut your pieces. You’re ready to assemble.

But your cuts aren’t square.

Your edges are chipped.

Your narrow rip nearly took your finger.

And you think: “If only I had the right tool…”

I’ve been there.

In 2015, I blew $180 on a “premium” crosscut sled. It wobbled. The fence wasn’t square. I returned it.

Then I built my own — from scrap plywood and a few screws.

Cost? $8.

Result? Perfect 90° cuts. Every time.

That’s when I realized: you don’t need expensive tools. You need smart jigs.

Jigs are your secret weapon.

They turn your basic table saw into a precision machine.

They keep your fingers safe.

They save you money.

And the best part? You can build the most essential ones for under $20 each.

Today, I’m giving you the exact 5 jigs I recommend to every beginner student — with simple plans, material lists, and why each one matters.

Total investment? $25.

Store-bought equivalent? $200+.

Let’s build your confidence — and your workshop — the smart way.

Why These 5 Jigs Will Transform Your Woodworking

Before we jump in, let’s be clear:

These aren’t “nice-to-haves.”

They’re non-negotiables for safe, accurate, repeatable work.

- Zero-Clearance Insert: Stops chip-out on veneers and melamine.

- Push Stick Pro: Keeps your fingers 6 inches from the blade — always.

- Crosscut Sled: Guarantees perfect 90° crosscuts (no more measuring twice).

- Thin Rip Guide: Makes narrow cuts safe (no more kickback nightmares).

- Miter Gauge Upgrade: Gives you precise, repeatable angles (no more guessing).

Build these — and you’ll outperform 90% of beginners with “pro” tools.

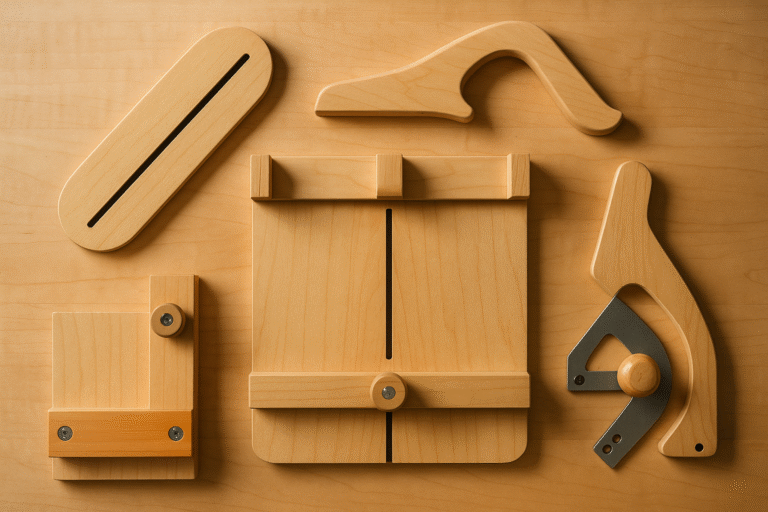

Jig #1: Zero-Clearance Insert ($3 Build)

What it solves: Tear-out on the bottom of your cuts — especially with plywood or veneers.

Why it works: The insert supports the wood fibers right next to the blade, so they don’t splinter.

Materials:

How to build it:

- Remove your existing throat plate.

- Place a piece of scrap plywood over the opening.

- Turn on your saw and slowly raise the blade through the plywood.

- Turn off saw. Remove insert. Sand edges smooth.

- Drop it into place.

🧑🔧 Daniel’s Story: I ruined a $60 sheet of birch plywood on my first cabinet project — all because of tear-out. I built this insert that night. Haven’t had a chip-out since.

Jig #2: Push Stick Pro ($5 Build)

What it solves: Getting your hand too close to the blade during narrow cuts.

Why it works: It gives you leverage and control — without risking your fingers.

Materials:

- Scrap ¾” hardwood (6” x 3”)

- Drill + ¼” bit

- Sandpaper

How to build it:

- Cut a “hook” shape: 6” long, 3” wide at base, tapering to 1” at top.

- Drill a finger hole near the top.

- Sand all edges smooth (no splinters!).

- Use it on every rip cut under 6” wide.

Safety Rule: If your hand is within 6 inches of the blade, you need a push stick. No exceptions.

Jig #3: Crosscut Sled Basic ($8 Build)

What it solves: Inaccurate crosscuts, uneven ends, and measuring errors.

Why it works: It slides in your miter slot, so your cut is always perpendicular to the blade.

Materials:

- ½” plywood (12” x 24”)

- ¾” hardwood runners (for miter slots)

- Wood glue, screws

- Square

How to build it:

- Cut base from plywood.

- Attach hardwood runners to the bottom (fit snug in miter slots).

- Glue a ¾” fence to the back, perfectly square to the blade.

- Test with a 5-cut method (or use your combination square).

Pro Tip: Add a stop block for repeatable cuts. Game-changer for shelves or boxes.

Jig #4: Thin Rip Guide ($2 Build)

What it solves: Dangerous narrow rips that can cause kickback.

Why it works: It acts as a zero-clearance fence on the left side of the blade, trapping the offcut.

Materials:

- Scrap ¾” hardwood (12” long)

- Clamp

How to build it:

- Clamp a straight scrap board to the left of your blade, just wider than your cut.

- Feed your workpiece between the fence and the guide.

- The offcut is trapped — no kickback.

🧑🔧 Daniel’s Story: I once had a ½” offcut shoot across my shop like a bullet. Scared me straight. Now, I never rip narrow stock without this guide.

Jig #5: Miter Gauge Upgrade ($7 Build)

What it solves: Wobbly, inaccurate miter cuts.

Why it works: Adds a long fence to your miter gauge, so your workpiece doesn’t pivot.

Materials:

- Scrap ¾” plywood (6” x 18”)

- Wood screws

- Your existing miter gauge

How to build it:

- Drill holes in the plywood to match your miter gauge’s mounting slots.

- Screw it to the face of the gauge.

- Add a stop block for repeatable cuts.

Result: Perfect 45° miters for picture frames. Clean dados. Accurate angles.

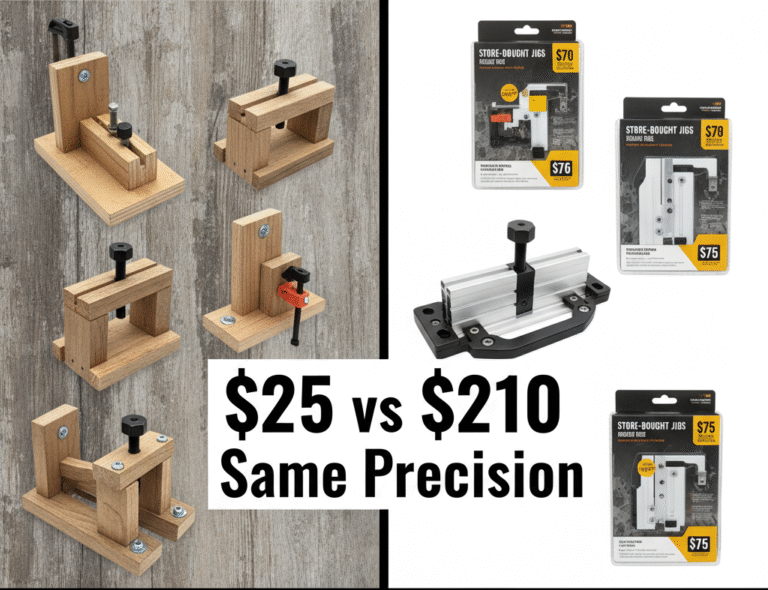

Total Investment: $25 vs $200+ Store-Bought

Let’s break it down:

Jig | DIY Cost | Store-Bought Cost |

|---|---|---|

Zero-Clearance Insert | $3 | $25 |

Push Stick Pro | $5 | $30 |

Crosscut Sled | $8 | $80 |

Thin Rip Guide | $2 | $20 |

Miter Gauge Upgrade | $7 | $45 |

TOTAL | $25 | $200+ |

You’re not just saving money.

You’re building skills, confidence, and pride.

And you’re proving something important:

You don’t need expensive tools to build beautiful things.

You just need to be smart.

Common Mistakes Beginners Make (And How to Avoid Them)

❌ Skipping the test cut → Always test your jig on scrap wood first.

❌ Using warped wood for jigs → Jigs must be flat. Use quality plywood or hardwood.

❌ Ignoring safety → If a jig feels unsafe, stop. Redesign it.

❌ Overcomplicating → Start simple. Add features later.

❌ Not labeling jigs → Use a Sharpie: “Crosscut Sled,” “Thin Rip Guide.” Saves time.

Wrapping It Up: Your Workshop, Your Rules

These 5 jigs aren’t the end.

They’re the beginning.

The foundation.

The first step toward a workshop where:

- Every cut is accurate.

- Every project is safe.

- Every tool is an extension of your skill.

Build them this weekend.

Use them on your next project.

Feel the difference.

Then — when you’re ready for more — I’ve got something for you.

🛠️ Ready for the Full System?

These 5 jigs are powerful.

But they’re just the start.

In The Table Saw Master’s Playbook, I’ve included 42 professional-grade jigs — with full plans, cutting lists, and video demos.

Jigs for:

- Perfect box joints

- Flawless tapers

- Dovetails on your table saw

- And 38 more

All designed to work with your existing tools.

All built from scrap wood.

All for $37.

Or if you’re not ready to buy…

👉 Download Our Free Jig Blueprint Pack

Let’s build something great — together.

— Daniel

HMZ Woodz